TIGHT HYDRAULIC MACHINE VISES

ERON

view

ERON

view

ERON

view

ERON

view

ERON

view

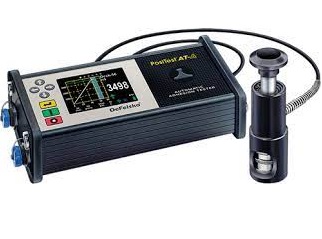

DEFELSKO

view

ERNST

view

ERNST

view

ERNST

view

ERNST

view

DEFELSKO

view

DEFELSKO

view

DEFELSKO

view