Mastering Material Hardness with a Professional Durometer

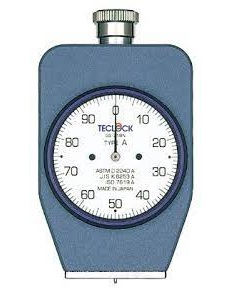

Accuracy is the foundation of quality control in the rubber and plastics industry. Therefore, a high-quality Durometer serves as an essential tool for every technician. This device measures the indentation hardness of various materials, from soft elastomers to hard polymers. By providing instant, repeatable results, it ensures your products meet exact engineering specifications.

How Does a Durometer Work?

A durometer functions by applying pressure to a material through a calibrated spring and a specialized indenter. Specifically, the depth of the indentation determines the hardness value on the Shore scale. Higher numbers represent harder materials, while lower numbers indicate softer, more flexible substances. Furthermore, this non-destructive testing method allows you to verify quality without damaging your final product.

Choosing the Right Shore Scale

The most common scales include Shore A and Shore D. Indeed, selecting the correct scale is vital for accurate data collection.

To measuring hardness by pushing by hand, durometer to work piece form the top

and read value by making pressed surface adhere to durometer.

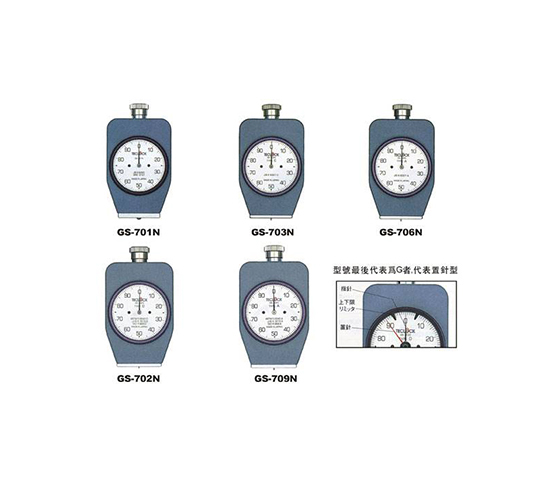

Determine by Shore A, B ,C , D, 00, 0 etc.

With & without maximum pointer

Key Benefits for Your Workflow

Moreover, modern digital durometers offer advanced features like data memory and peak-hold functions. By using these, you can capture the maximum hardness reading instantly. Additionally, the ergonomic design allows for comfortable use during long inspection shifts. These tools help you maintain ISO standards and prevent the use of sub-par raw materials.

Boost Your Quality Assurance

In conclusion, don't leave your material properties to guesswork. A reliable Durometer provides the scientific certainty your customers demand. Ultimately, it is a small investment that prevents costly production errors. Upgrade your testing lab today with the industry's most trusted hardness testers.