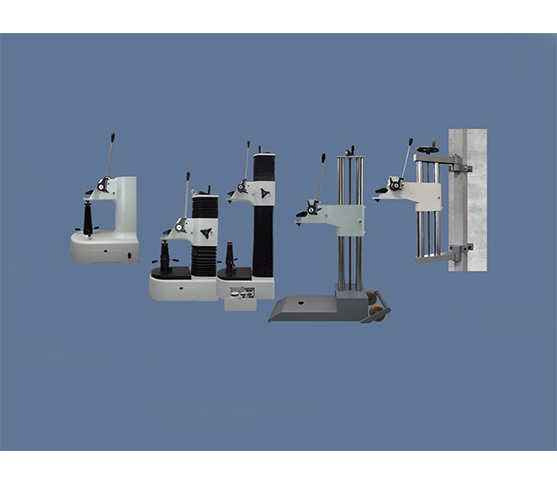

KING Tester Brinell Hardness: Industrial-Grade Material Testing Solutions

Ensure material integrity with KING Tester Brinell Hardness equipment—the trusted choice for metalworking facilities, foundries, and quality control laboratories. Our testers deliver accurate, repeatable Brinell hardness measurements compliant with ASTM E10 and ISO 6506 standards.

Why Choose Brinell Hardness Testing?

The Brinell method excels where other techniques fall short. Using a 10mm tungsten carbide ball indenter, it provides superior accuracy for coarse-grained materials, castings, and forgings. The large impression area averages material variations, delivering reliable results for non-homogeneous metals.

KING Tester Key Features:

-

Durable Construction: Heavy-duty frame ensures long-term reliability in demanding environments

-

Precision Optics: Integrated measuring microscope provides clear indentation visualization

-

Flexible Operation: Choose from manual or motorized loading systems to match your workflow

-

Wide Capacity Range: Models available for various force requirements and material types

Ideal Applications:

-

Foundry and casting quality assurance

-

Heat treatment verification processes

-

Welding procedure qualification testing

-

Automotive and aerospace component inspection

Technical Specifications:

-

Compliance: ASTM E10, ISO 6506, and JIS standards

-

Test Forces: 1839-3000 kgf (standard range)

-

Ball Indenters: 10mm tungsten carbide standard

-

Measurement Range: Covers all common industrial metals

KING Tester Brinell Hardness equipment combines robust construction with precise measurement capabilities. Our testers feature user-friendly operation and minimal maintenance requirements, making them ideal for daily industrial use.

Upgrade Your Quality Control Today

Contact us to find the perfect Brinell hardness tester for your specific application requirements and budget considerations.

Our

Service Center are able to repair with original parts and guided calibration according to ASTM-E10