Achieving Total Precision with a Run Out Gauge

In mechanical engineering, even a tiny wobble can lead to a massive failure. When a shaft or gear rotates, it must remain perfectly centered. Consequently, a run out gauge—often referred to as a dial indicator—is the essential tool for detecting these hidden imperfections.

What is a Run Out Gauge?

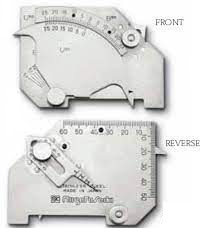

A run out gauge measures the "wobble" or eccentricity of a rotating component. It consists of a sensitive plunger connected to a needle or digital display. As the part rotates, the gauge tracks any deviation from a perfect circle. Usually, engineers measure two types: radial run out (side-to-side) and axial run out (end-to-end).

Why Is This Measurement Critical?

Even a microscopic deviation can cause significant problems at high speeds. If you ignore run out, you will likely face these issues:

-

Excessive Vibration: This leads to noisy operation and operator discomfort.

-

Premature Wear: Bearings and seals fail much faster than expected.

-

Poor Surface Finish: In machining, run out creates "chatter" marks on the workpiece.

-

Machine Damage: Persistent imbalance can destroy expensive spindles.

How to Use a Run Out Gauge Effectively

To get an accurate reading, you must follow a careful process. First, mount the gauge on a stable magnetic base. Next, position the tip so it touches the surface of the part. Then, rotate the part slowly by hand for one full turn. Finally, observe the "Total Indicator Reading" (TIR). This value represents the difference between the highest and lowest points on the dial.

Maintenance for Long-Term Accuracy

To keep your run out gauge precise, you must treat it with care. For example, never drop the tool or snap the plunger. Additionally, keep the contact point free of oil and metal chips. By maintaining this tool, you ensure your machinery runs smoothly for years.

Ultimately, detecting run out early saves time and money. It is the best way to guarantee professional results in any machine shop.

Enables easy concentricity measurements using test indicator.

Wide Selection of Base Length, rollers and carrier.

Provide 2um maximum accuracy.

A fine angle adjustment carriage to offer easy Zero setting.

Equipped with "work stopper" that stops the movement during measurement.

Factory specification can measure diameter not more than 45mm.