Precision Coating Thickness Gages for Non-Metal Surfaces

Measuring paint on metal is standard, but how do you measure coatings on wood or concrete? Traditional mechanical tests often damage the surface. Fortunately, modern Coating Thickness Gages for Concrete, wood, and plastic solve this problem. These ultrasonic tools provide accurate readings without leaving a scratch. They serve as the gold standard for inspectors in the construction and composite industries.

How Ultrasonic Technology Works

Unlike magnetic gages, these devices use sound waves to determine thickness. The probe sends a high-frequency pulse into the coating. This pulse travels through the layer and reflects off the substrate. The gage then calculates the time taken to determine the exact thickness. This technology works perfectly on glass, composites, and even polyurea. It allows you to verify quality control standards instantly on the job site.

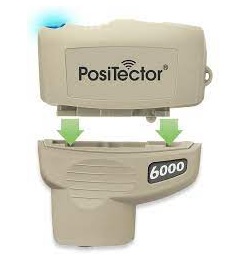

Key Features of the PosiTector 200

The PosiTector 200 series leads the market in non-destructive testing. It offers several advantages for professional inspectors:

Coating Thickness Gages for Concrete, Wood, Plastic, Glass, Composites and more..

DF200 Features:

* Ready to measure—no adjustment required for most applications.

* NEW Larger 2.8” impact resistant color touchscreen with redesigned keypad

for quick menu navigation

* NEW On-gage help explains menu items at the touch of a button.

* RESET feature instantly restores factory settings

Durable

* NEW Weatherproof, dustproof, and water-resistant—IP65-rated enclosure

* NEW Ergonomic design with durable rubberized grip

* Shock-absorbing protective rubber holster for added impact resistance.

* Two-year warranty on gage body AND probe

Accurate

* Responsive transducers provide fast, accurate readings

* Certificate of Calibration showing traceability to NIST or PTB included.

* Proven non-destructive technique conforms to ASTM D6132 and ISO 2808

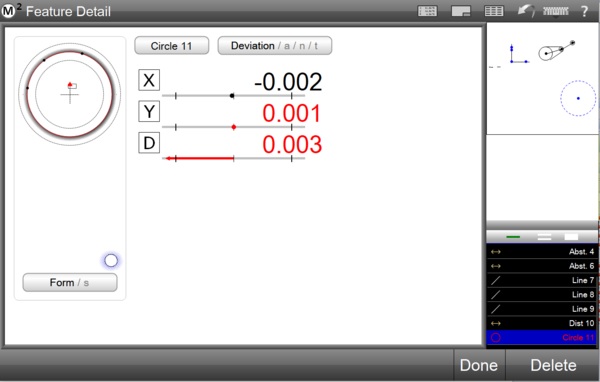

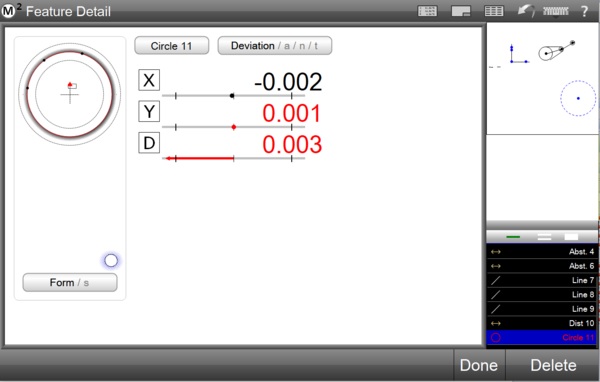

Advanced Multi-Layer Measurement

Some advanced models can even measure individual layers in a multi-coat system. This is vital when you need to know the thickness of the primer versus the topcoat. The clear, sunlight-readable display shows all your data at a glance. You can store thousands of readings and generate professional PDF reports directly from the device.

Improve Your Inspection Standards

Stop using destructive methods that require expensive repairs. Choose a reliable coating thickness gage to protect your materials and your reputation. These tools ensure every project meets the specified thickness requirements perfectly. Accuracy on non-metal surfaces has never been easier to achieve.