Mastering Quality with Welding Gauges

In the welding industry, visual inspection is the first line of defense against structural failure. To ensure a joint meets safety standards, inspectors must go beyond a simple glance. Consequently, welding gauges are the primary tools used to verify dimensions and identify defects accurately.

What are Welding Gauges?

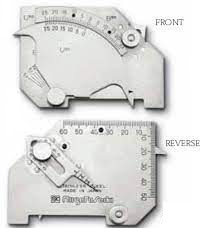

Welding gauges are precision instruments designed to measure various parts of a weld. For example, they check the size of a fillet weld, the height of a reinforcement, and the depth of an undercut. Because they come in various shapes—such as the Bridge Cam or V-WAC gauge—they can handle almost any inspection task.

Why These Tools Are Essential

Accuracy in welding prevents catastrophic errors. If a weld is too small, it may not hold the required load. On the other hand, overwelding wastes expensive filler metal and increases heat distortion. Using a welding gauge provides several key benefits:

-

Code Compliance: You can prove your work meets AWS or ISO standards.

-

Safety: Accurate measurements ensure the joint can handle its design stress.

-

Cost Efficiency: You avoid wasting time and materials on unnecessary repairs.

How to Use a Fillet Weld Gauge

Using a standard fillet gauge is very straightforward. First, select the gauge that matches the specified weld size. Next, place the curved edge against the toe of the weld. Finally, check if the blade tip touches the center of the weld face. This quick check confirms if the throat thickness is sufficient.

Maintaining Your Gauges

To keep your tools reliable, you must keep them clean. Wipe off soot and metal shavings after every use. Furthermore, store them in a protective case to prevent bending the thin measuring blades.

Ultimately, a set of high-quality welding gauges is a small investment that protects your professional reputation. It ensures every bead you lay is safe, strong, and precise.

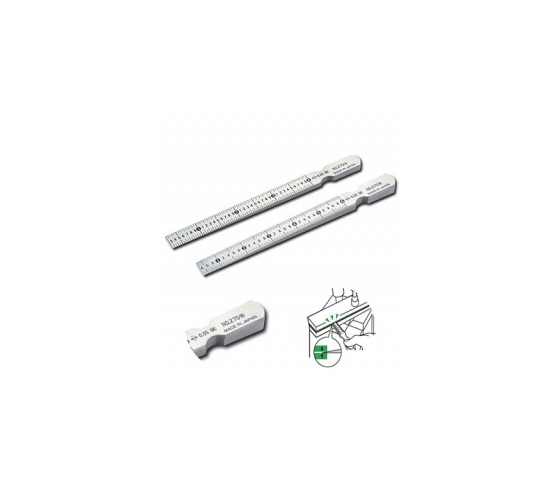

Measure undercut depth/ Groove angle/ Inconsistent level

Height of fillet weld & bead weld/ Throat thickness of fillet

Root opening/ Plate thicknessExternal diameter of circular workpiece

Stainless steel (SUS420J2)