Measuring massive, complex parts often creates a logistical nightmare. Traditional laser trackers offer range but struggle with hidden points. Portable arms provide detail but lack the reach for large assemblies. The Super 6DoF TrackArm bridges this gap. It creates a unified 3D measurement system that measures anything, anywhere, with zero compromise.

Eliminate Line-of-Sight Restrictions

Line-of-sight issues frequently stall production lines. Standard trackers lose connection when an object blocks the beam. This system solves that problem instantly. You can reach behind obstacles, inside cockpits, or under machinery using the integrated ScanArm.

The tracker locates the arm in real-time. This allows you to move the arm freely around the part. You maintain high accuracy even in hidden areas that a laser beam cannot reach.

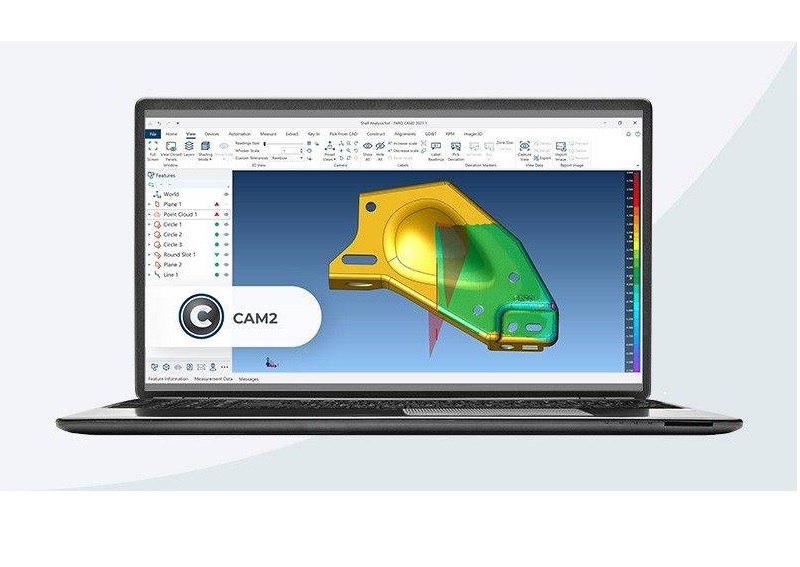

Seamless Workflow Integration

Efficiency drives modern manufacturing. This solution integrates the long-range precision of a Vantage Laser Tracker with the high-resolution flexibility of a Quantum ScanArm.

-

Huge Volume: Measure across an expansive working volume without repositioning the tracker.

-

Unified Data: All data flows into a single coordinate system automatically.

-

Versatility: Use the tracker and arm independently when you do not need the combined power.

Boost Your Bottom Line

Stop wasting time moving devices and stitching data. This system reduces scrap and accelerates your inspection cycles. You get precise data faster, which allows your team to make smarter decisions on the spot. Manufacturers in aerospace, automotive, and heavy machinery already trust this technology to validate their most critical components.

Upgrade your metrology capabilities today. The Super 6DoF TrackArm delivers the freedom and accuracy your facility needs.

Ready to see it in action? Request a virtual demonstration now.