Instrument Setting & Length measurement

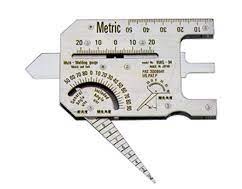

JOINT INSTRUMENT

view

JOINT INSTRUMENT

view

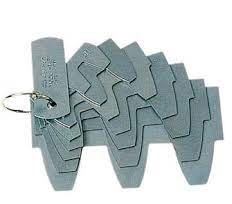

JBO

view

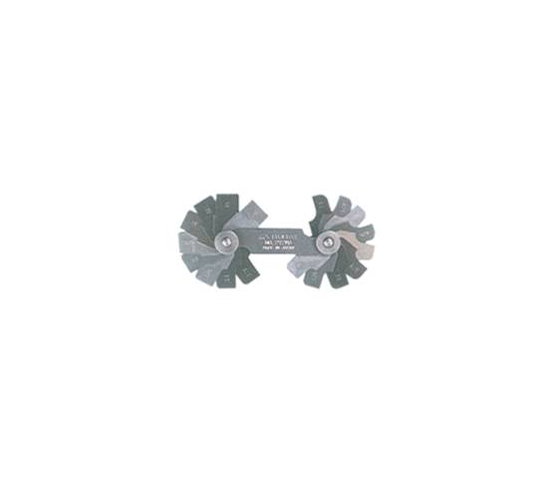

FUJI TOOL

view

FUJI TOOL

view

FUJI TOOL

view

FUJI TOOL

view

FUJI TOOL

view

FUJI TOOL

view

FUJI TOOL

view

HASBERG

view

ERON

view

ERON

view