Upgrade to Precision with a Digital Durometer

Manual testing often leaves too much room for human error. Therefore, switching to a Digital Durometer is the smartest move for modern quality control. These devices provide clear, numerical readings that eliminate the guesswork of analog dials. Whether you test soft rubber or rigid plastics, a digital interface ensures every measurement remains consistent and reliable.

The Digital Advantage in Testing

Why do professionals prefer digital models over traditional ones? Specifically, digital durometers offer superior resolution and data stability. Most models feature a large LCD screen that displays the hardness value instantly. Furthermore, many versions include a peak-hold function. This captures the highest reading during the test, which is critical for materials that "relax" under pressure.

Essential Features of Digital Models

Modern digital testers provide more than just a number. Indeed, they offer a suite of tools that improve your daily workflow.

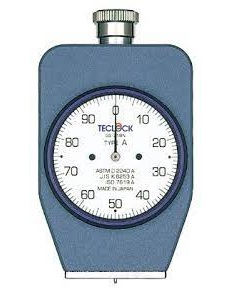

This is the model for which peak hold function is mounted

This is effective to measure hardness of Elastomer of which

maximum value is unreadable due to relaxation phenomenon.

Determine by Shore A, B ,C , D, 00, 0 etc.

Streamline Your Documentation

Moreover, these tools help you comply with international standards like ASTM D2240. Many digital units store multiple readings in their internal memory. By doing so, you can calculate averages without using a separate calculator. Additionally, the rugged construction protects the sensitive electronic sensors from industrial dust and impacts.

Invest in Professional Accuracy

In conclusion, don't settle for approximate values in your lab. A Digital Durometer provides the scientific precision that modern manufacturing demands. Ultimately, it speeds up your inspection process and boosts customer confidence. Upgrade your testing equipment today to experience the future of hardness measurement.