MX3-500N Standard Type Motorized Test Stand

IMADA

view

IMADA

view

PREMIUM

view

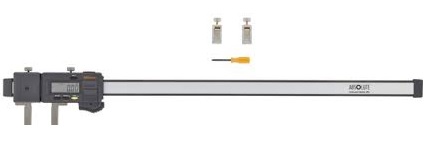

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

DEFELSKO

view

DEFELSKO

view

DEFELSKO

view

ERNST

view

PREMIUM

view