Advanced Material Testing with Ultrasonic Portable Hardness Testers

Quality control professionals across industries face the constant challenge of verifying material hardness without compromising component integrity. The ultrasonic portable hardness tester emerges as the ideal solution, combining precision measurement with complete portability for comprehensive on-site material analysis.

Using Ultrasonic Contact Impedance (UCI) technology, these innovative devices measure hardness by analyzing frequency shifts when a vibrating rod contacts the material surface. This advanced methodology enables accurate conversions across major hardness scales including Rockwell (HRC, HRB), Brinell (HB), and Vickers (HV).

Key benefits of ultrasonic portable hardness testers include:

-

Non-Destructive Testing: Minimal indentation preserves component integrity

-

Unmatched Portability: Lightweight design enables testing in any orientation

-

Rapid Results: Instant measurements with laboratory-grade accuracy

-

User-Friendly Operation: Intuitive interface requires minimal training

These testers prove particularly valuable for:

-

Quality assurance in manufacturing

-

Weld inspection and heat-affected zone analysis

-

Large component testing where mobility is essential

-

Preventive maintenance programs across industries

Modern ultrasonic hardness testers feature robust data management capabilities, with Bluetooth connectivity and internal memory supporting comprehensive quality documentation. Their rugged construction ensures reliable performance in demanding industrial environments.

Transform your material verification process with ultrasonic portable hardness testing technology. Experience the efficiency of accurate, non-destructive hardness measurement wherever your quality control needs take you.

Ideal for: Metal fabrication plants, aerospace manufacturers, automotive suppliers, and energy sector applications.

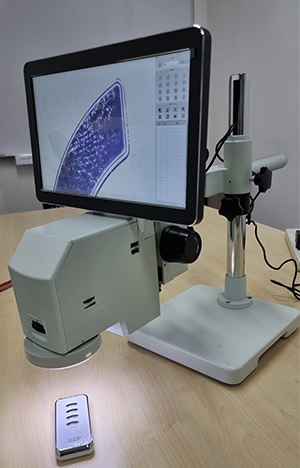

The Combined Hardness Tester NOVOTEST T-UD3 allows user to measure the hardness of any metals, parts of any shape and thickness, measure the hardness of the surface hardened layers and evaluate the tensile strength.