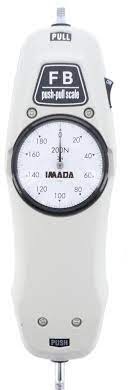

IMADA Digital Force Gauge: Precision, Durability, and Innovation in Measurement

When it comes to precise and reliable force measurement, IMADA Digital Force Gauges stand out as a leading solution in various industries. Known for their accuracy and versatility, these gauges are indispensable tools for quality control, product testing, and research & development.

IMADA Digital Force Gauge provide high-precision readings, capable of measuring both tension and compression forces. With advanced digital displays and user-friendly interfaces, these force gauges ensure accurate results for professionals in manufacturing, automotive, electronics, and more. Whether you’re testing the tensile strength of materials or measuring assembly line forces, IMADA Digital Force Gauges offer unmatched accuracy and ease of use.

One of the key advantages of IMADA's digital force gauge is their robust construction. Designed for durability, they can withstand rigorous use in industrial environments. With features like peak hold, data output capabilities, and multiple unit options (N, kgf, lbf), IMADA gauges ensure that users get reliable data every time.

IMADA's commitment to innovation shines through in their continuous development of cutting-edge technologies for force measurement. Their range of gauges is designed to meet the diverse needs of industries while maintaining exceptional performance standards.

In conclusion, IMADA Digital Force Gauge combine precision, durability, and ease of use, making them an essential tool for anyone needing accurate force measurements. Explore the best in force measurement technology with IMADA to optimize your testing processes today.

Advanced application for industrial used High Performance Digital Force Gauge ZTA/ZTS

Region Suppliers Distributor of IMADA Japan

Measure Push & Pull force of industrial application

Range : 200gf -500kgf

Selectable Unit: Kg / LBS / N.

Accuracy : +/- 0.2% F.S.

Sampling Rate : 2000 times / second

Overload Capacity : 200% of the F.S.

Output Function : USB, RS232, etc.