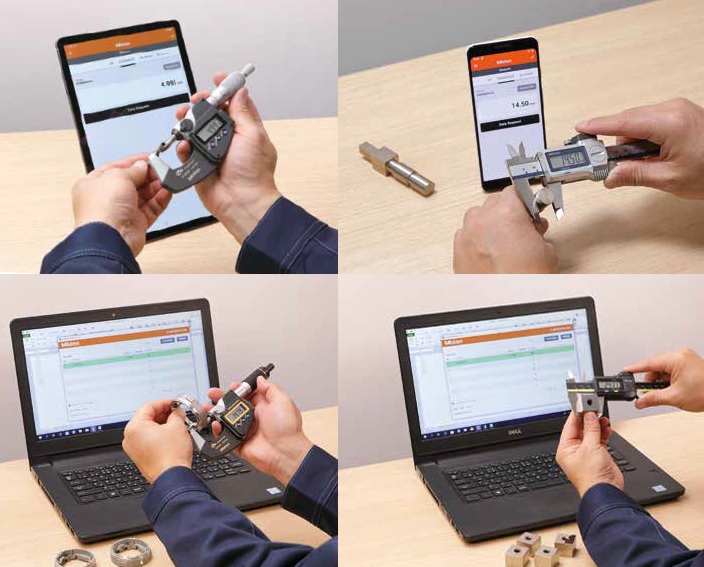

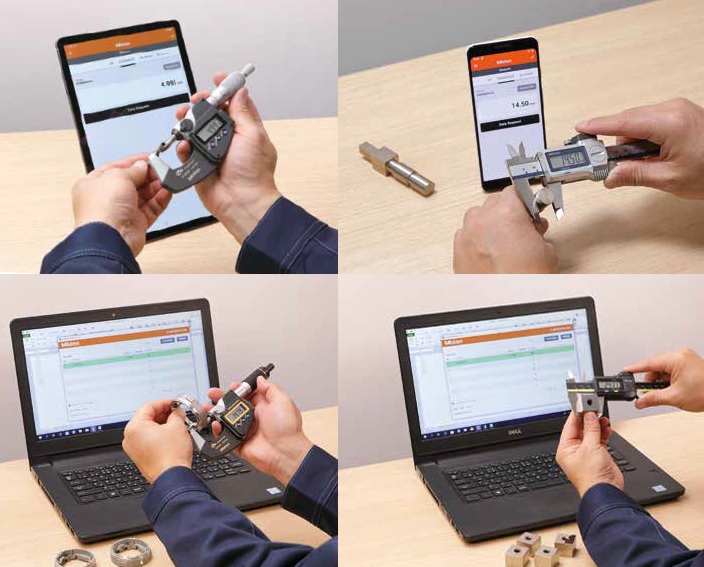

Bluetooth U-Wave Data Communication System

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view