Surface Profile Gage

DEFELSKO

view

DEFELSKO

view

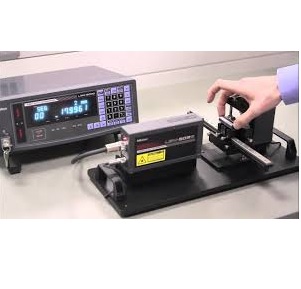

MITUTOYO

view

MITUTOYO

view

MITUTOYO

view

PREMIUM

view

MITUTOYO

view

MITUTOYO

view

IMADA

view

PREMIUM

view

IMADA

view

DEFELSKO

view

DEFELSKO

view