Latest Events

-

DeFelsko at APM 2026 Read More >

-

LH-600 Linear Height Gage Read More >

-

LUNA Precision Balances Read More >

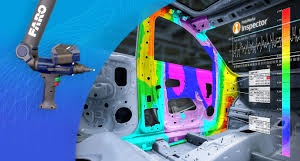

Quality control isn’t just about finding errors; it’s about process confidence. As manufacturing tolerances shrink, your metrology software must do more than just collect points. PolyWorks|Inspector™ stands as the premier 3D dimensional analysis solution. It bridges the gap between raw data and actionable engineering insights.

Most shops struggle with fragmented workflows. One software handles the CMM, while another manages handheld scanners. PolyWorks eliminates this silo. It offers a universal software platform that interfaces with all major 3D measurement devices. Whether you use a laser tracker, a structured light scanner, or a tactile probe, your team stays within a single interface. This consistency reduces training costs and prevents data translation errors.

Real-Time Feedback: High-speed point cloud digitizing provides instant visual guidance. This allows operators to catch defects immediately.

Automated Inspection: Users can update an entire inspection project automatically after a design change. This “play-to-inspect” technology saves hours of manual rework.

Advanced GD&T: The software features a robust GD&T engine. It simplifies complex compliance checks and ensures parts meet strict global standards.

Repeatability: You can build logical inspection scripts without needing complex coding knowledge. This ensures every part is measured exactly the same way every time.

By integrating PolyWorks into your workflow, you reduce measurement time and eliminate human error. It transforms a standard “pass/fail” check into a deep dive into your manufacturing health. The software identifies trends before they become scrap. Don’t just inspect your parts—master your process.