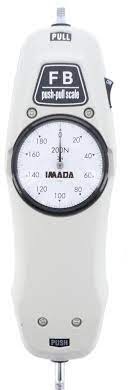

IMADA Mechanical Force Gauge FS/FB series

What is a Mechanical Force Gauge? A Guide to Push-Pull Testing

Meta Description: Learn about mechanical force gauges for accurate push and pull force testing. Discover how they work, their key benefits, and common applications in quality control.

A mechanical force gauge is an essential tool for measuring tension and compression forces (push and pull) in pounds, kilograms, or Newtons. Unlike digital models, these instruments use a precision spring mechanism and analog dial for direct, reliable readings without needing batteries.

Key Benefits of Mechanical Force Gauges

Why choose a mechanical gauge? The advantages are clear:

-

Durability and Simplicity: With no electronic components, they are robust, withstand harsh environments, and require minimal maintenance.

-

No Power Required: Ready to use anytime, anywhere—no batteries or power outlets needed. This eliminates downtime.

-

Cost-Effective: They typically offer a lower initial investment than digital force gauges, providing excellent value.

-

Real-Time Response: The analog dial provides an immediate, easy-to-read measurement, ideal for fast-paced production lines.

Common Applications

Mechanical force gauges are vital across numerous industries for quality control and product testing. Common uses include:

-

Peak Load Testing: Determining the breaking point of wires, seals, and components.

-

Spring Testing: Measuring the compression and extension force of springs.

-

Quality Checks: Verifying the actuation force of buttons, switches, and keyboards.

-

Package Testing: Ensuring peel strength on seals and adhesives.